Choosing the Right Insulation for Your Custom Home

Choosing the right insulation for your custom home

An air tight, highly insulated building envelope is one of the most effective methods for helping to reduce your home’s energy consumption and lower your carbon footprint. Therefore, the type of insulation you decide to use in your home is critical.

An improperly specified or low grade insulation can cost you significant amounts of money down the road. Each month, unnecessary amounts of heat can leak either in or out of your home’s poorly insulated walls through thermal breaks and tiny unsealed air gaps. This will cause your A/C to work harder to heat or cool the internal spaces to a comfortable temperature. The extra energy needed to keep your leaky home at a stable and comfortable temperature will show up as increased cost in your utility bills each month. When we frame this topic in terms of money lost or saved, the subject of insulation gets much more interesting for homeowners.

What Are The Types of Insulation?

There are four general types of insulation on the market today; batt insulation, loose insulation, spray foam insulation and rigid insulation. Considering the performance, cost, toxicity, environmental impact, durability, and method of installation is important when choosing which product to install. The two topics that homeowners usually want to discuss are cost and R-Value. The R-Value is the insulation value of the product. The higher R-Value the better insulation value.

Batt Insulation

Batt insulation is the most common type of insulation on the market. When insulation is brought up, this is the type that comes to mind for most homeowners. Batt insulation is probably the most common type of insulation used in residential and light commercial construction. It is inexpensive, easy to install, and can usually provide the required code minimum insulation value.

It is made of glass wool or fiberglass and usually faced with a kraft paper or foil. Batt insulation is installed between joists, studs and beams, Typically it is stapled to the framing members to fasten in place. Although the rolls typically come in standard joist and stud spacing to fit nicely within the framing members, there will always be locations where the installation will be imperfect and gaps will be left uninsulated and unsealed.

Although batt insulation can provide the code required insulation values on a conventional wood framed home with 6” exterior walls, it can’t achieving the R-30/R-40 insulation values that we are starting to see in the walls of energy efficient net zero homes. For every inch of thickness, fiberglass batt insulation can only provide roughly an R-2.2. For this reason we try to urge owners to invest a bit more money upfront and upgrade to a superior insulation system.

Blown-In Insulation or Loose-Fill Insulation

Blown-In insulation is made of cellulose, mineral wool, cotton, perlite or fiberglass. It comes in the form of shreds, granules or nodules. It is used in places where other types of insulation would be difficult to install. Blown in Insulation is great for remodels or retrofits because you can fill hard to reach places. If you choose to use blown-in insulation, your installer will need to hook up a blower machine which will add extra costs to the install.

Blown-In insulation has been used for decades to fill the floors of attic spaces. It is usually quicker to install than batt insulation and costs less. Most types of blown-in insulation are considered renewable. For example cellulose can be made from recycled newspapers.

The insulation value of blown in insulation depends on the density and thickness of the layer. Because it is loose it can fit into and fill smaller voids in the framing. For our ground up, new construction projects, we usually do not consider using blown in insulation. We rarely design homes with attics and if we were to, our preference would be to insulate the roof joists rather than the floor of the attic.

Spray Foam Insulation

Spray foam insulation is supplied in two parts and mixed at the spray head nozzel. When mixed the two products react with each other and produce a low density foam that adheres to the substrate or framing. The two main benefits of spray foam insulation are its exceptional insulation capabilities and its ability to expand, conform, and adhere to different shaped cavities. As the foam conforms to the cavity and expands, it seals any gaps from potential air leaks.

There are two general types of spray foam insulation; closed-cell and open-cell. Closed cell products have a higher R Value however they usually contain ozone depleting chemicals in the blowing agent. Open cell products have lower R values but the blowing agent is usually a non toxic substance such as water.

Closed-cell spray foam can provide higher R-Values compared to open cell and can also serve as a vapor/air barrier in some cases. Open-cell spray foam can serve as your air barrier, however it typically does not work as a vapor retarder.

The two negative characteristics of spray foam insulation is the high embodied energy (energy required to produce the product) and sometimes high levels of toxicity depending on the product.

If we choose to use spray foam insulation in a project, we will typically specify a product such as Icynene. Icynene is a water based HCFC free open celled insulation. In other words it uses water as the blowing agent rather than a toxic chemical. If we are working on a project with a conventional wood stud exterior wall assembly, we feel that a spray foam insulation such as Icynene is the best option.

With open cell spray foam you can achieve roughly an R-Value of 3.7 per inch while with closed cell spray foam you can achieve an R-Value of up to 6.5 per inch.

Rigid Foam Insulation

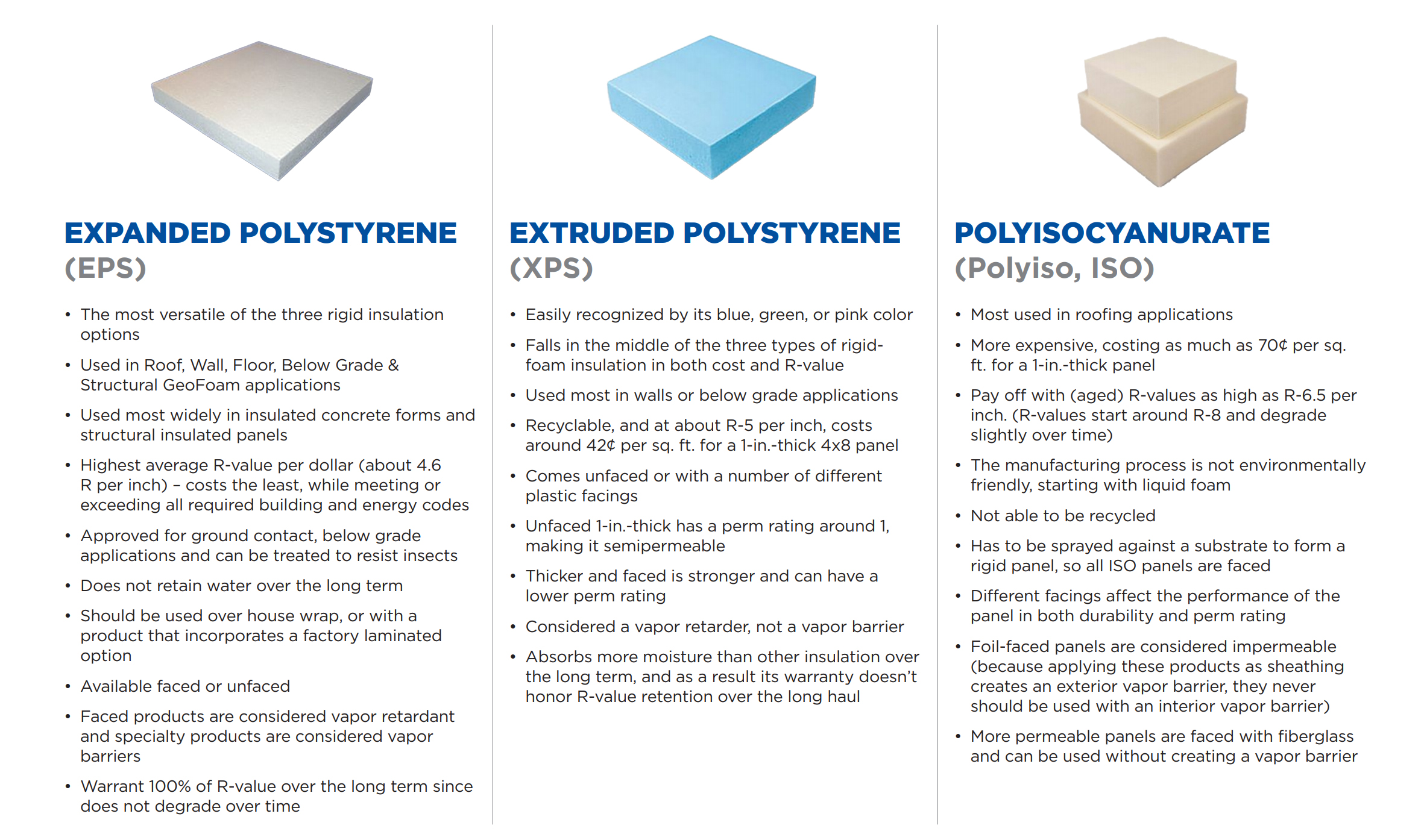

Rigid Foam insulation is often used as exterior roof insulation over roof sheathing, as exterior wall insulation over the wall sheathing, or below grade for foundation insulation. The primary benefit of rigid insulation is its high R-Value. For example a Polyiso rigid insulation can have up to a 6.8 R-Value per inch of thickness compared to a batt insulation which has roughly a 2.2 R-Value per inch of thickness.

Rigid insulation is created by forming different varieties of organic and/or inorganic materials into rigid boards. There are three main types of rigid insulation; Polyiso, XPS, and EPS.

PolyIso

Polyiso is typically used for above grade applications such as roof and wall assemblies. Polyiso can absorb water so we recommend not using it for below grade installations where there is a lot of moisture. If you are using it in roof or wall assemblies, it must be protected by a water resistive barrier. It has the highest R-Value of all the rigid insulation products and is often the most expensive.

EPS

Expanded polystyrene (EPS) is a closed cell product. EPS is commonly used in roof or wall assemblies. EPS is manufactured without using ozone depleting chemicals and have proven to be a versitile insulation product with high R Values. EPS can often provide the highest R-Value per dollar compared to the other rigid foam insulation products.

XPS

Extruded plolystyrene (XPS) is a closed cell product. XPS is typically more expensive than EPS however it has higher insulative qualities. It can provide insulation values of around R-5, similar to polyiso. The main difference between polyiso and XPS is their performance in moist conditions. XPS is water resistive and is great for protected roof assemblies and below grade insulation, whereas polyiso is not suitable for wet conditions.

Both XPS and polyiso are durable products and can withstand relatively high compression and job site wear and tear. The polyiso historically has been slightly less expensive than XPS however the cost difference is minimal.

XPS and EPS are commonly used in products such as concrete ICF’s. To read more about ICFs (insulated concrete forms) check out our article here.

Rigid insulation comparison diagram. Courtesy of insulfoam.com

Choosing the right insulation for your project depends on many variables and should be reviewed on a case by case basis. The information presented here is general and is not a recommendation or suggestion for the type of insulation to install on your project. Depending on the climate zone, location, budget, construction type and the unique qualities of your project, the type of insulation we would recommend may vary significantly. If you would like to discuss your specific project, please feel free to reach out to us on the Contact Page at www.rostarchitects.com.